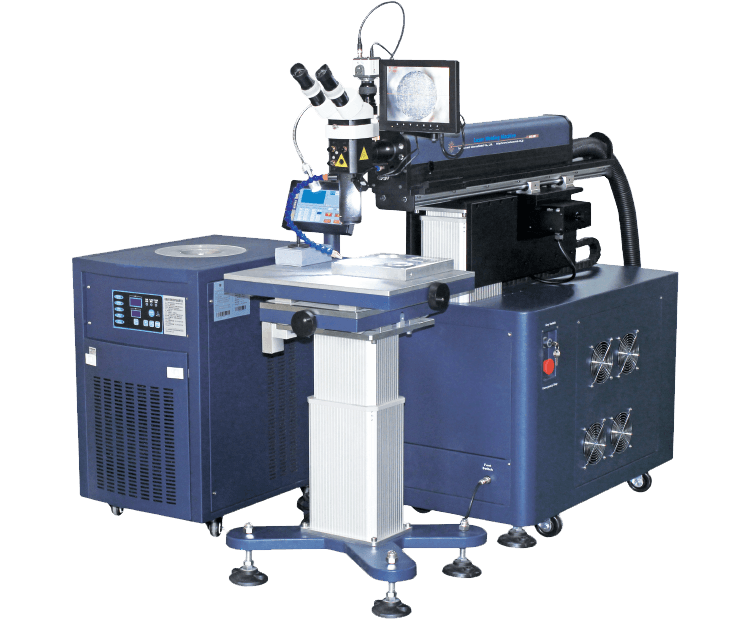

【STL-150】

Laser welding of pulse YAG laser covering/welding equipment

Laser welding of pulse YAG laser covering/welding equipment

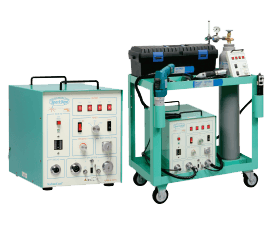

It is miniaturized and lightweight based on SparkDepo

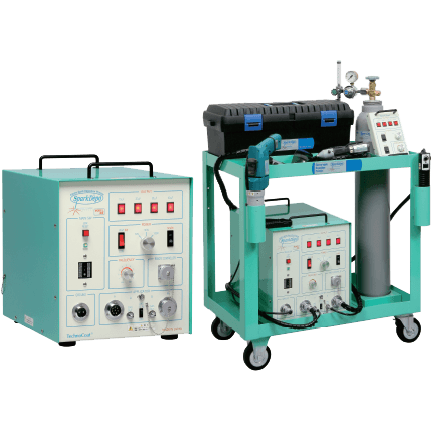

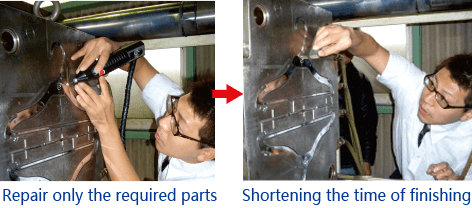

This model is Japan original install big power model.Simple operation, high quality of coating and surfacing

It is miniaturized and lightweight based on large ESD

To achieve localization based on the Japanese original installation.The price of the machine has been greatly reduced

Electro-Spark·Welding machine

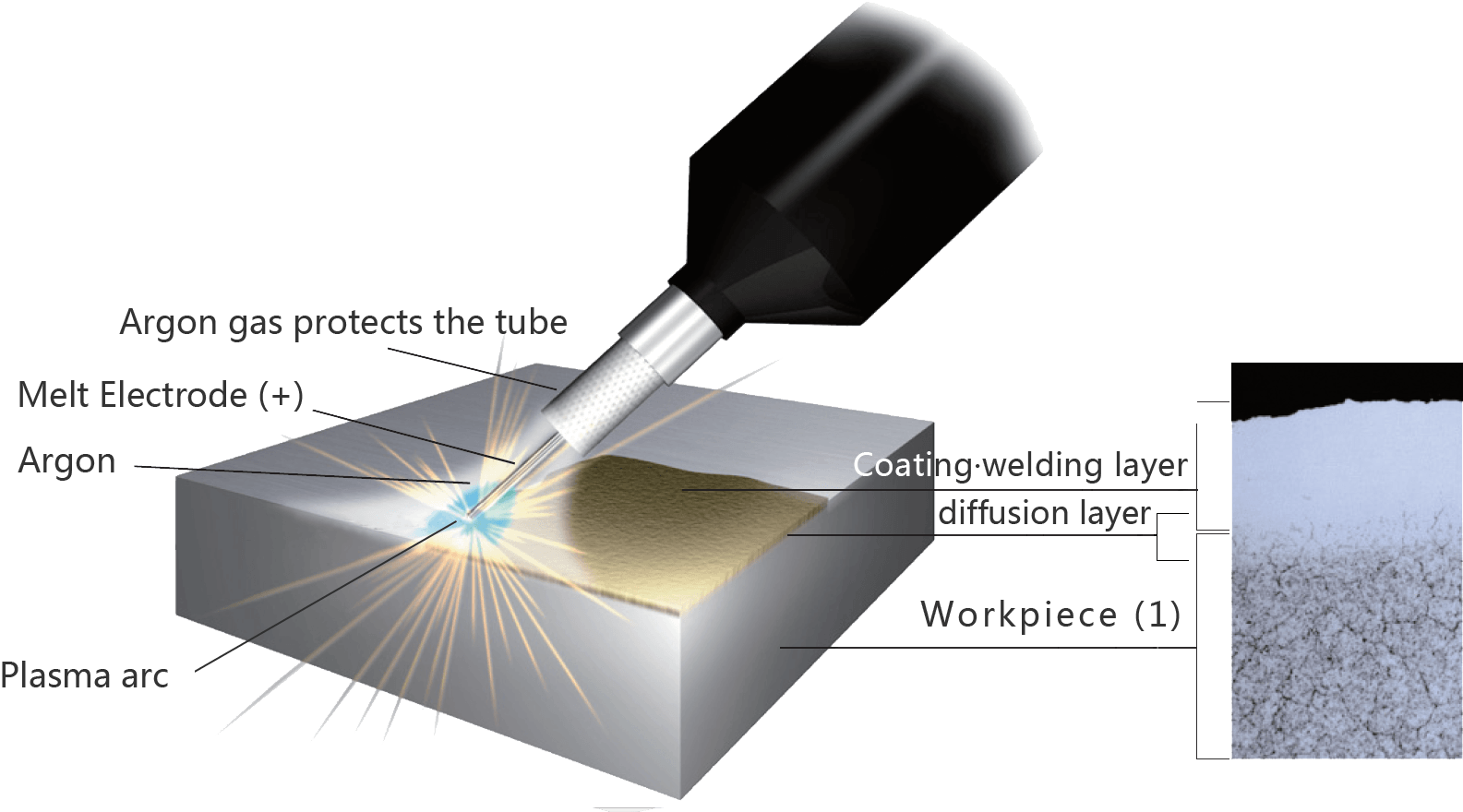

The use of EDM (EDM) principle of surfacing and coating equipment

According to the principle of discharge will be soluble electrode infiltration, the accumulation of the workpiece surface coating, surfacing machine

It is miniaturized and lightweight based on SparkDepo

This model is Japan original install big power model.Simple operation, high quality of coating and surfacing

It is miniaturized and lightweight based on large ESD

To achieve localization based on the Japanese original installation.The price of the machine has been greatly reduced

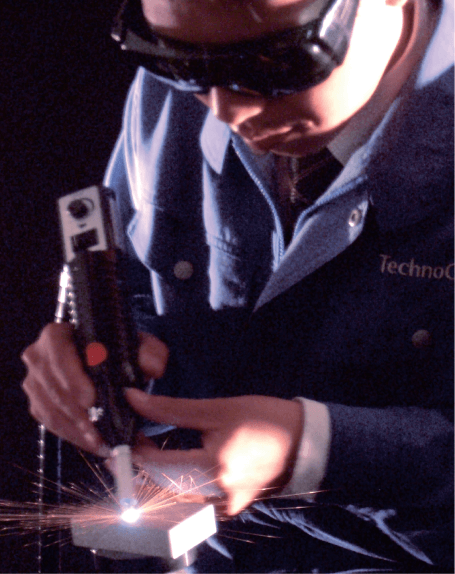

After the capacitor in the host is fully charged, the temperature of the contact between the fused electrode and the workpiece reaches 8,000 to 25,000 ° C in the period of 10-3 to 10-1 seconds and the ultra short pulse width of 10-6 to 10-5 seconds C, in the plasma state fused electrode infiltration to the workpiece surface, resulting in alloying, resulting in a combination of high strength.

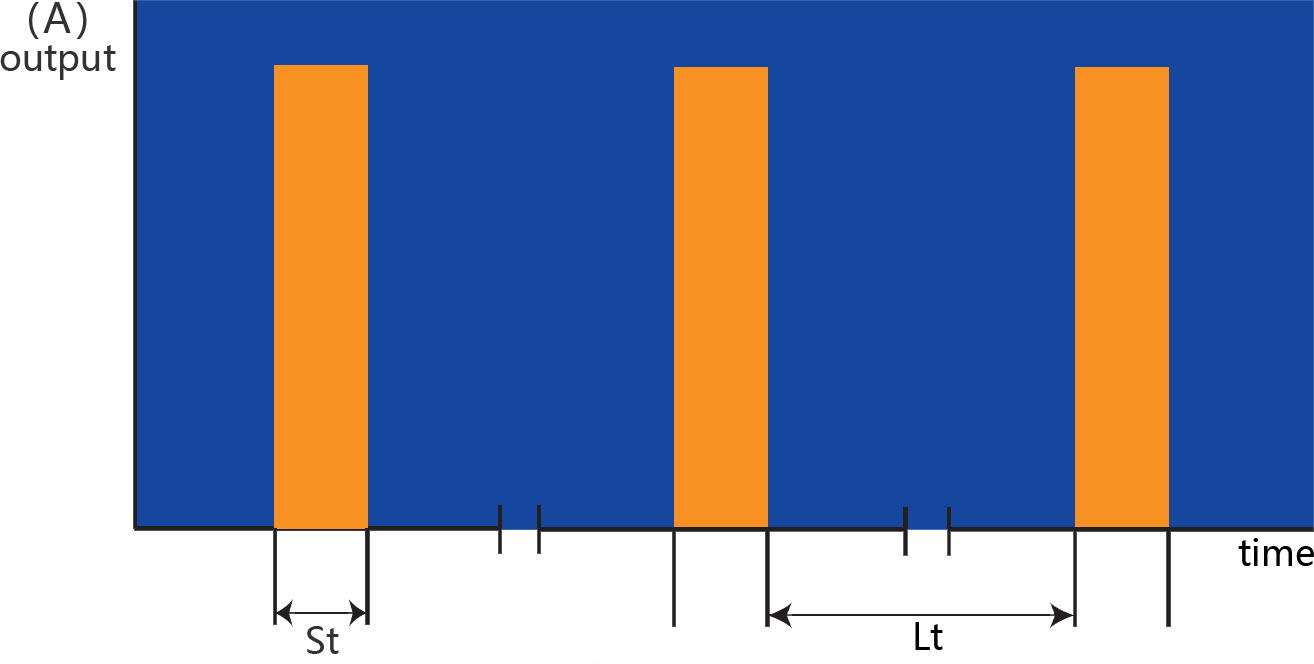

As the discharge time (pulse width) is short, the intermittent time is long, the heat of the processing site is sufficiently diffused, so the heat input is low.

The fusible electrode is deposited to the workpiece while a strong diffusion layer is formed on the surface of the workpiece. So the combination of high strength.

It is suitable for low carbon steel, medium carbon steel, tool steel, die steel, cast iron, cast steel, stainless steel, aluminum alloy, nickel copper mold and almost all electric conductors.

Electroplating, spraying, CVD, PVD, TD treatment, nitriding, carburizing, quenching, welding and so on.