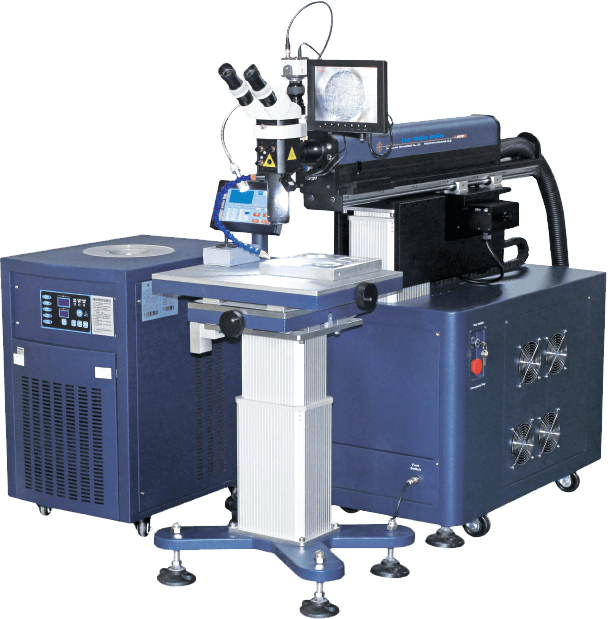

【STL-150】

Laser welding of pulse YAG laser covering/welding equipment

Laser welding of pulse YAG laser covering/welding equipment

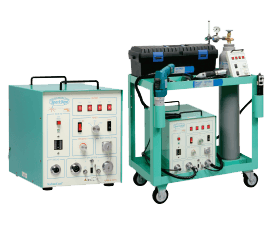

It is miniaturized and lightweight based on SparkDepo

This model is Japan original install big power model.Simple operation, high quality of coating and surfacing

It is miniaturized and lightweight based on large ESD

To achieve localization based on the Japanese original installation.The price of the machine has been greatly reduced

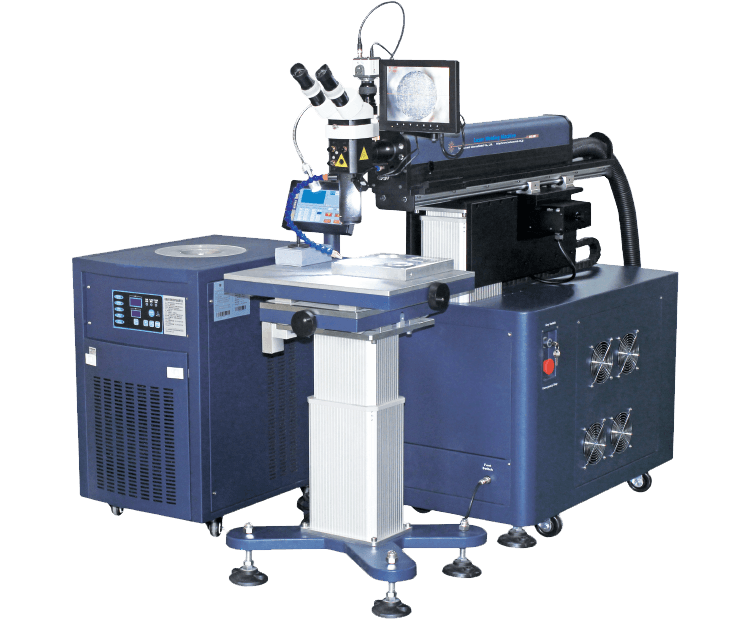

Japan laser repair · welding machine

For precision repair and welding, the traditional welding method is difficult to achieve !

Laser to achieve a precision repair and welding !

Only laser can be done to repair and welding !

① Simple operation

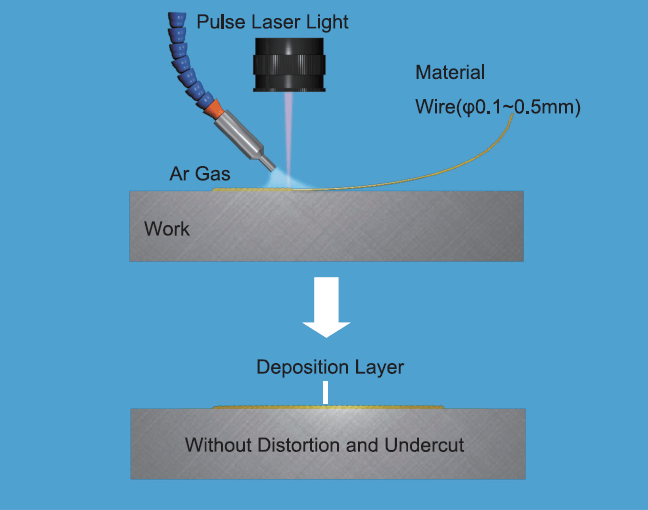

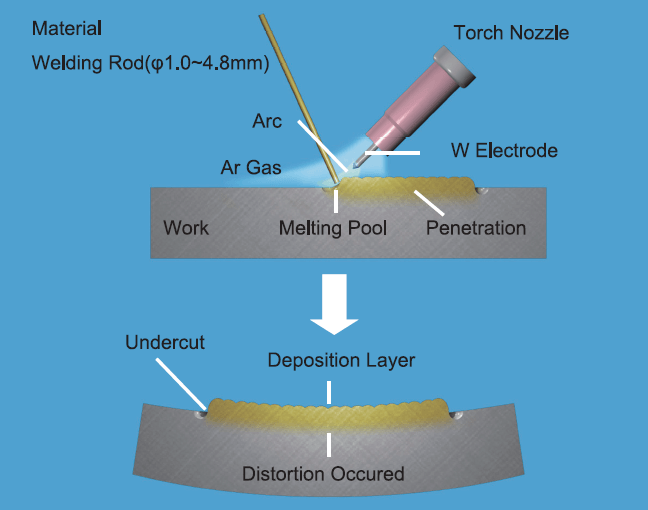

② Low heat input (no deformation, no stress, no undercut, no oxidation)

③ Able to carry out high-precision repair (to reduce the finishing time and cost)

④ For the narrow groove, the bottom of the hole, side, within the right angle can be patched

⑤ No preheating and insulation

When the amount of repair is large, the repair speed is slower.

① Quick fix

② Easy to operate in the field

① Need superb welding technology

② Heat input large (easy to produce deformation, stress)

③ Prone to undercut

④ Welding more meat (finishing time and cost)

⑤ Narrow groove and the bottom of the hole • side of the repair more difficult