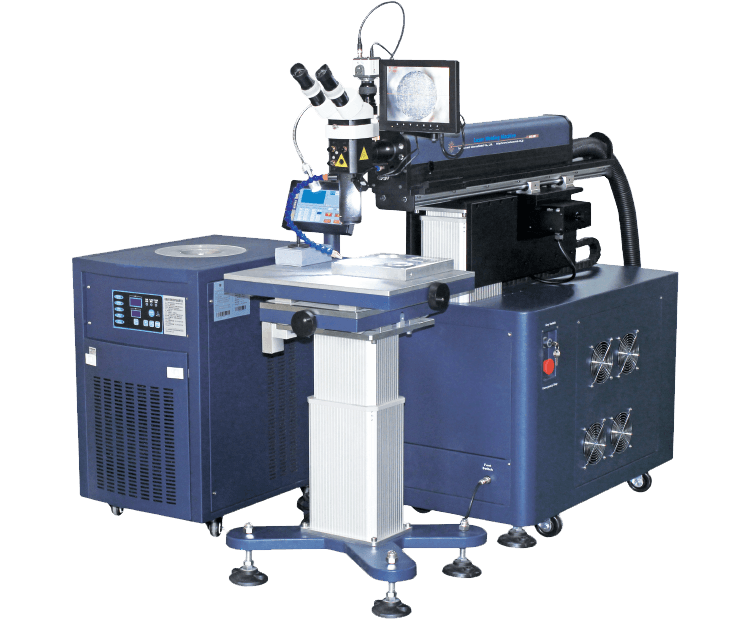

【STL-150】

Laser welding of pulse YAG laser covering/welding equipment

Laser welding of pulse YAG laser covering/welding equipment

It is miniaturized and lightweight based on SparkDepo

This model is Japan original install big power model.Simple operation, high quality of coating and surfacing

It is miniaturized and lightweight based on large ESD

To achieve localization based on the Japanese original installation.The price of the machine has been greatly reduced

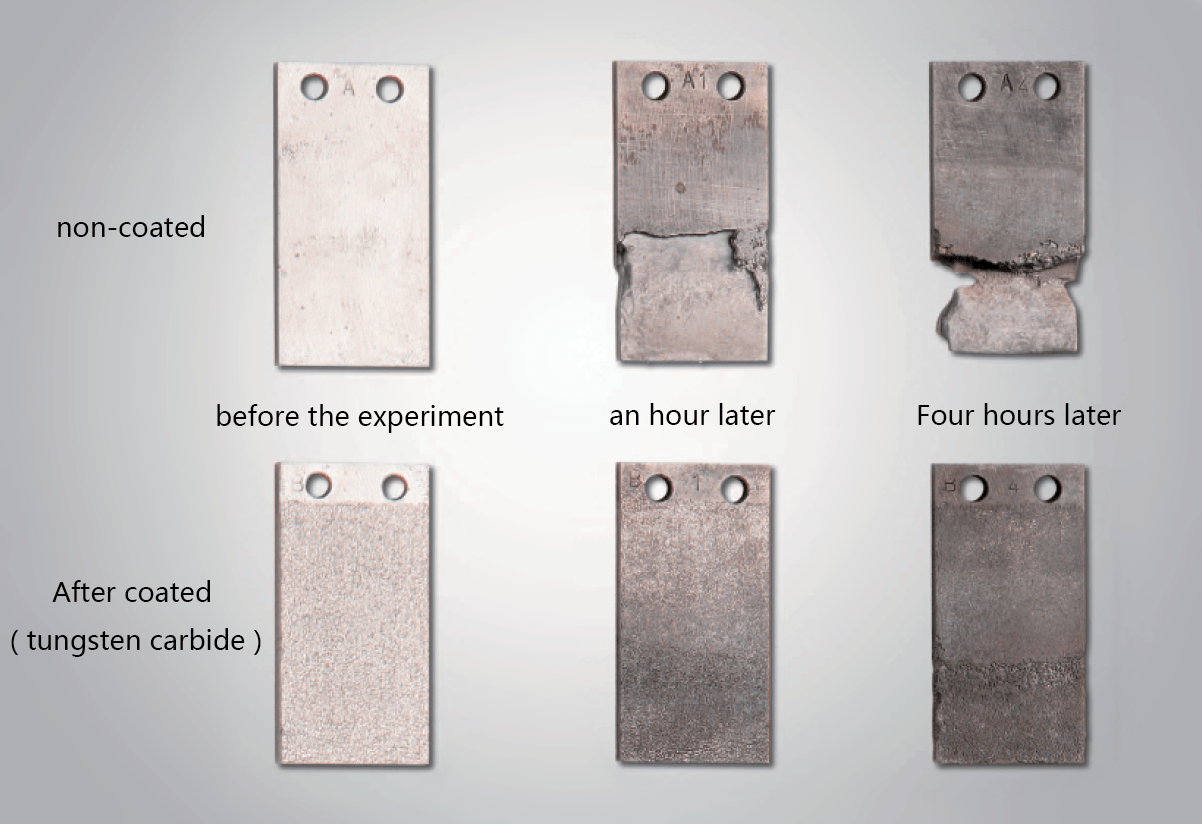

The use of WC, TiC, Cr3 C2 and other wear-resistant, heat-resistant, burning sticky, corrosion-resistant, resistant to oxidation of the material coating, can protect the mold, mechanical parts, tooling, etc., to extend its life.

Experimental conditions Specimen: SKD-61 Melt metal: ADC-12 (680 ° C) Immersion in molten metal at 30 RPM

Compared with the untreated specimen, the amount of melt loss after coating is only 1/10

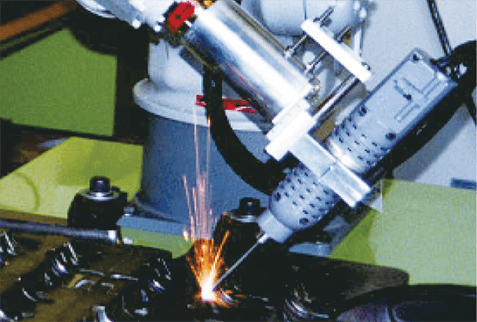

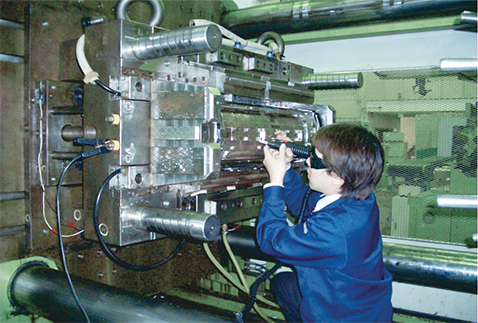

Aluminum die-casting mold

Use a coating manipulator to coat the casting mold

Through the surfacing to repair molds, mechanical parts such as scratches, bite mold, wear, corrosion, pinholes and processing errors and other defects.

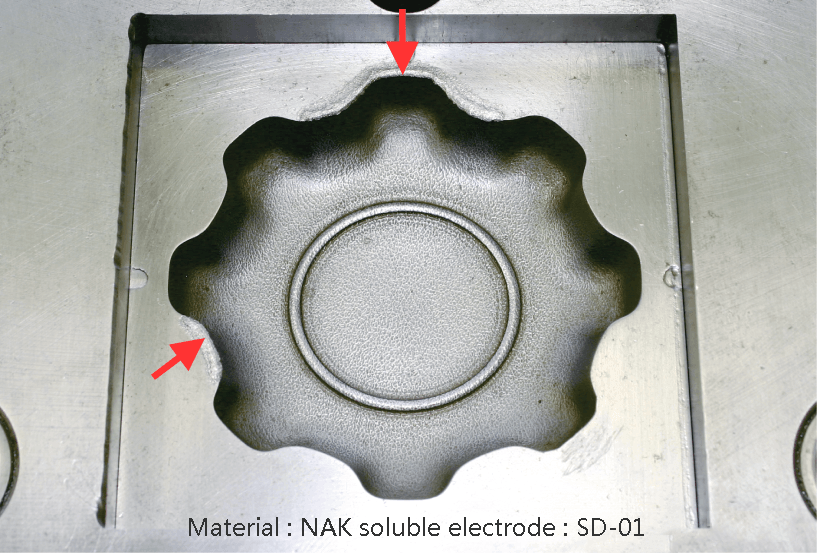

Workpiece : Injection mold ( mold cavity as a whole ).

Problem : Product glitches ( TIG welding has an effect on etch ).

Processing methods : Surfacing ( no heat, corrosion will not be destroyed ).

Mold without demolition, in the injection molding machine can be on the burrs of the parting surface for surfacing repair, and then use a small grinding machine, rasp, Whetstone and other parts of the welding on the finishing.

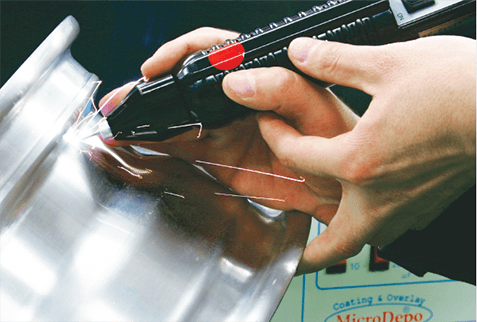

Surfacing Repair of Automobile Aluminum Ring Pinhole